How To Test a Run Capacitor Under Load

Checking run capacitors under load is an alternative method to shutting down power to a system and checking in the traditional manner by using the uF (microfarad) setting on your meter.

I would always recommend checking capacitors with the power off.

From a safety standpoint, reaching into an electrical cabinet with the power off compared to reaching into a live electrical cabinet is always the safer option.

But, there are some circumstances where the system may need to continue running during testing, if perhaps the system is serving a critical environment or you are trying to perform a set up of system controls and are unable to kill the power.

Follow the procedure below.

How To Check Run Capacitors Under Load

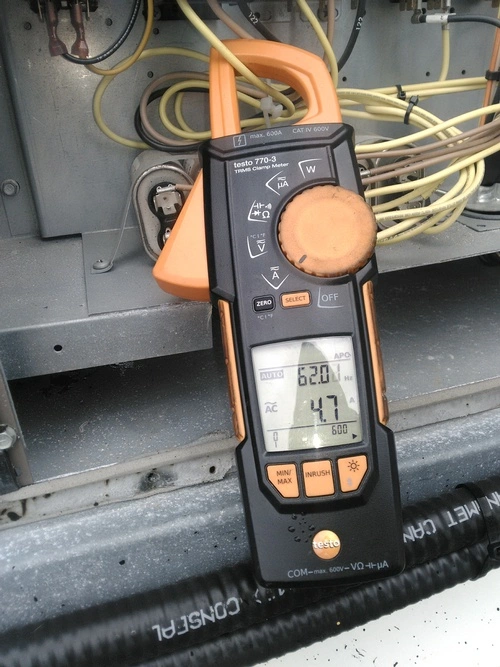

1. Set your clamp meter to amps and take an amp draw reading of the motor start winding wire connected to the capacitor, and note the reading.

2. Now, set your meter to volts and take a reading across the capacitor that will give you the back electromotive force (EMF) of the motor; note the reading.

3. Plug your readings into the following formula below…

4. Start winding amps x 2650 (constant) / Back EMF

The above procedure will spit out the microfarad reading under load. Run caps are stamped with a +/- percentage, if your calculation falls within that +/- range, you should be good to go.

Check out the video below for a demo of the above explanation

Finally!

Check out the link to my YouTube channel for more tips, tricks, and troubleshooting videos, and check out The HVAC Know It All podcast or on your favorite podcast app.

Happy HVACing…