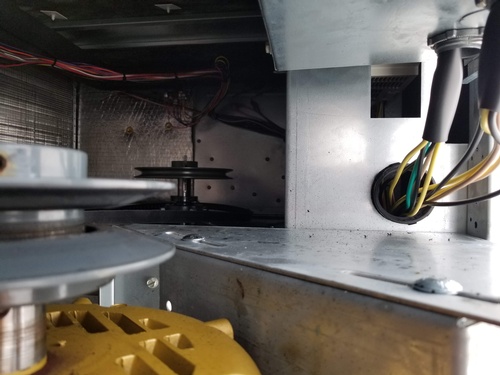

During my career I have come across many pulleys, shafts, blower wheels and bearings that have come loose due to improper set screw tightening, sadly a lot of this equipment was brand new or close to new. On some larger equipment or equipment that may be susceptible to excessive vibration, a thread lock compound would be recommended. Keep in mind that when using a thread compound they do come in different strengths and in most cases, it could be difficult to dismantle or tear down parts in the future if necessary. The video below shows an easy but effective way to tighten set screws whether or not you choose to use locking compound or not.

Check out the link to my YouTube channel for more tips, tricks, and troubleshooting videos and check out the The HVAC Know It All podcast here or on your favourite podcast app. Happy HVACing…