Heat Pump Reversing Valves and Their Control Designation

O/B Terminals

As Gary mentioned in a recent podcast, reversing valves are used in heat pumps to direct the flow of refrigerant, depending on the demand for heating or cooling.

Also mentioned was the fact that reversing valves have a default position when they are not energized.

Most manufacturers at this point default to heat (O terminal is energized for cooling), though some still default to cooling (B terminal is energized for heating).

Below is a list of manufacturers that use B because it is less common:

- Rheem

- Ruud

- Weathermaker

- Ameristar

- Bosch Air Source (WSHP uses O)

Another consideration with heat pumps is light commercial systems.

Many manufacturers will still use traditional heat pump control wiring for their systems, but a handful actually use conventional wiring, much like you’d see with a gas furnace with AC.

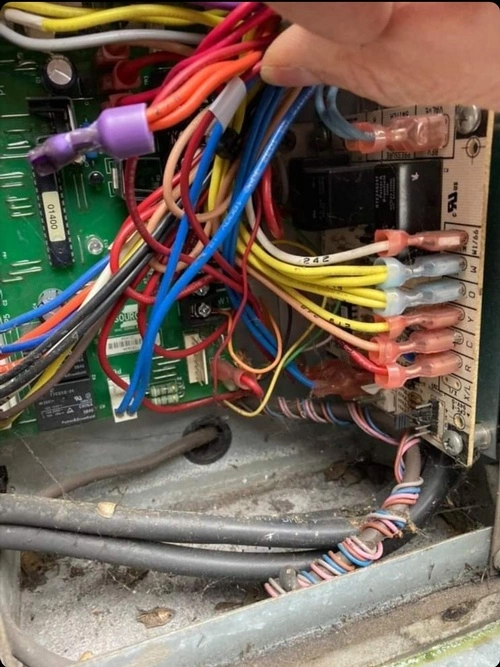

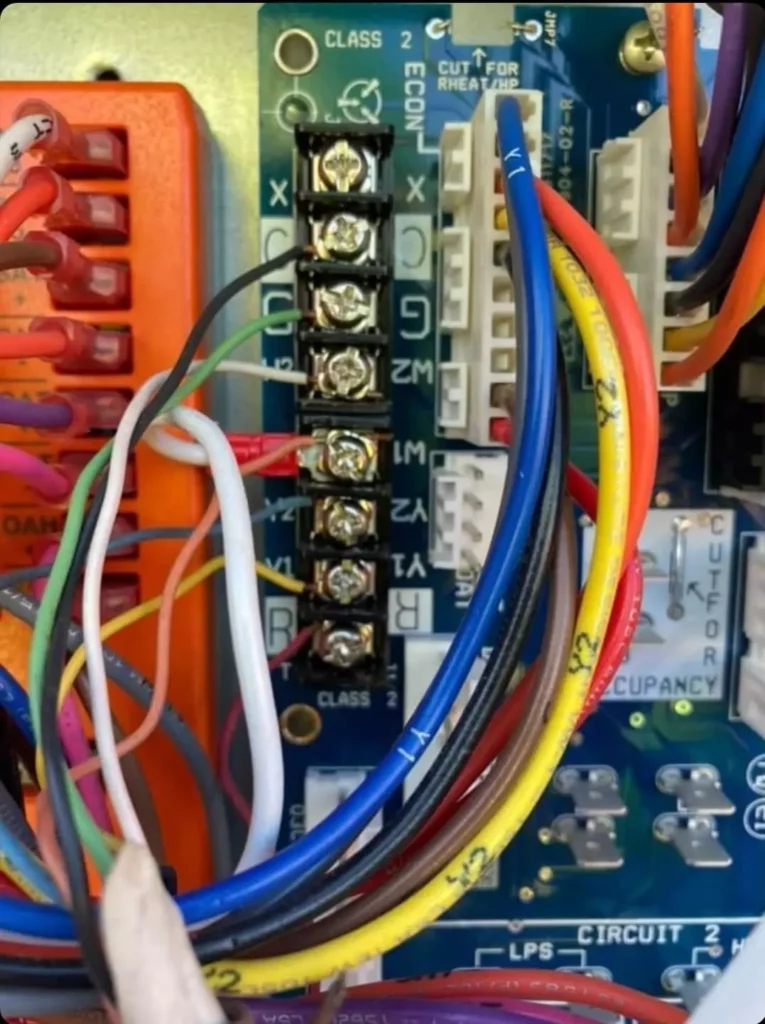

The most notable examples that I have encountered are Carrier and York.

These systems, regardless of cooling stages, use W1 to energize all compressors for heating and W2 to energize auxiliary heat.

This is because on a call for Y1, the control signal goes through the economizer control first (in an RTU application) before potentially energizing the stage one compressor contactor.

W1 then is used to bring on all compressors for heating for a couple reasons: it bypasses this economizer control, ensuring no unnecessary outside air enters the airstream, it brings on all the compressors because we are not concerned about latent heat removal, and it allows the logic board to determine the appropriate heat pump reversing valve position.

With Carrier specifically, these logic boards are used in tandem with either a defrost board in their heat pumps or an ignition control board for their gas furnace RTUs.

I Would Also Like To Add a Note To This

Back in the day, I worked on packaged water-cooled heat pumps in ceiling spaces where they used mercury thermostats to control them.

These heat pumps failed in heating, so a call for W1 would run the heat pump in heating mode.

To run in the cooling mode, they took an interesting approach.

A call for Y1 would energize the reversing valve, and a call for Y2 would pull in the contactor for the compressor.

The building had many heat pumps throughout many floors that were wired this way. Gary McCreadie

RTFM

As with any system, the most important thing that anyone can do is to RTFM: read the fantastic manual.

This ensures that the system you’re working on is wired and set up properly at the thermostat.

Finally

The HVAC Know It All Podcast is the perfect way to stay up to date on the latest industry news and information.

Hear from experienced professionals to help keep you sharp and give you an edge over the competition regarding knowledge and understanding of the trade.