Confession

I have a confession to make. Yes, I use internal HVAC sealants.

I guess you’re going to have to keep reading to understand why.

Internal sealants in the HVAC/R industry have been given a bad rap, rightfully so, as the older polymer-based sealants would react to moisture and air and be the cause of potential system blockages.

There were also technicians that would ignore the process of a system leak check and add a can of sealant without much of a diagnosis, this actually still happens quite often but I’m here to help with a little education.

Service call on a frozen coil

The Right Approach

Before we get into using a leak sealant product, we need to understand a few things first, is there a leak?

Where is the leak?

Is it repairable in a cost-effective way?

If a technician first discovers the system is short of refrigerant, adding leak sealant and walking is not acceptable.

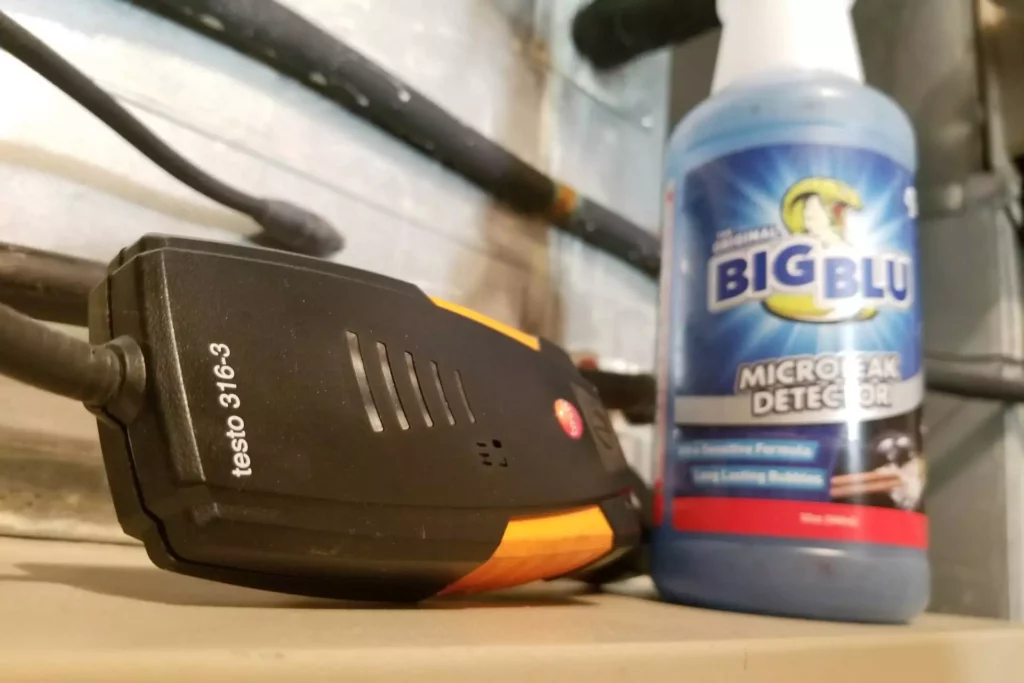

The technician should perform a leak inspection, my suggestion is with an electronic leak detector and then with soap to verify its presence.

Most leak detectors can pick up a very low leak rate, so in some cases, bubbles may not appear.

In the right circumstance, dye can be used.

As I stated, in the right circumstance it is actually very effective, especially in thicker evaporator coils that contain 5 rows or more.

Once the leak is found, determine if the repair can be performed in the traditional manner, brazing or cutting off and re-flaring a bad flare joint, for example.

If you happen to find a leak in a porous evaporator, most likely, the copper within the coil has succumbed to formicary corrosion and has become relatively fragile.

Cutting into a coil in this condition to access the leak point can lead to more leaks, especially if the coil is in bad shape.

At this point, a coil replacement is your best bet for a successful repair.

Butchering into an old coil and spending time to do so may not be so cost-effective to the customer, you’ll have to judge for yourself and, as I stated above could cause more damage to an already fragile hunk of metal.

Sometimes, the system is critical, or the coil is not available, and the customer needs to be up and running yesterday.

This is where a trained technician that is educated on various options available may use an internal sealant.

Remember, installing a sealant is a customer option that should be explored in the “correct” scenario and application to get a system up and running again.

Product Testing

This is where I’m going to be biased, only because I have tested this product in many different applications, ranging from walk-in boxes to reach-ins to a Liebert unit inside of a small data center.

December of 2017 was the first time I used AC Smart Seal.

Since I’ve used it 10-15 times, all units were well out of warranty and had leaking evaporators.

I can report that not one system has had a failed compressor or blocked metering device.

The simple reason is that the product is an oil-based formula, not polymer-based.

Furthermore, as per the manufacturer, it doesn’t react to air or moisture.

In fact, it’s inert and non-reactive.

It acts mechanically, as refrigerant is forced from the leak site, the oil-based sealant is dragged along with it, for lack of a better phrase, and the elastic molecules begin to aggregate, creating a seal.

Does it work in every situation, no!

The leak needs to be small enough for it to work.

If you notice a large leak on a braze joint, repair it.

If you’re dealing with a seasonal mystery leak or find a corroded evaporator coil contributing to your problem.

An internal leak sealant could be a candidate.

It will give you a runway of operation until a more suited repair can be made or scheduled, depending on the nature of the application.

Listen to an old-school episode of the HVAC Know It All Podcast discussing internal sealants

Case Study

Early in 2021, I found a frozen evaporator coil on a Liebert unit.

I allowed it to thaw and determined the system was short on refrigerant charge, we had a leak.

The system had dye previously added many years prior, and my leak detector was sensing a leak in and around the evaporator.

Due to the size of the coil and the location of the leak, soap wasn’t going to work to pinpoint the location.

I used a black light and discovered a very small leak.

Again, due to location not exactly fixable in a cost effective way.

Because of the age of the machine, I talked about replacement with the customer, but in the meantime, they were on board with trying out a sealant.

I educated the customer on my past experience with AC Smart Seal, and they had nothing to lose at this point.

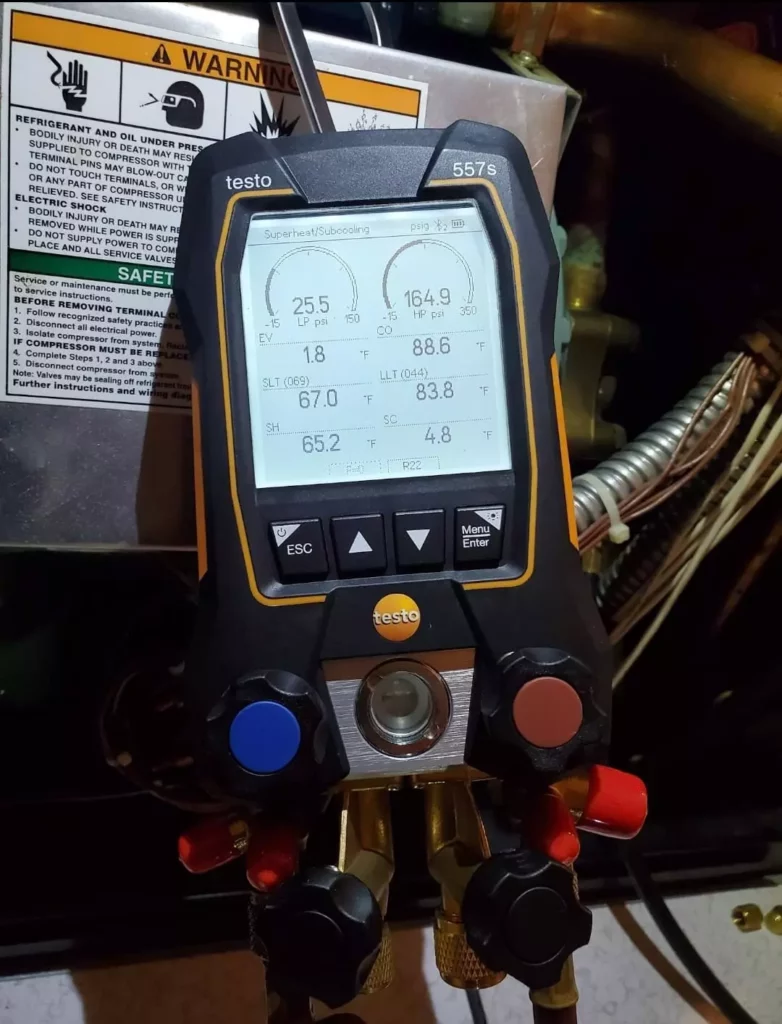

Diagnoses to determine the system was low on refrigerant charge

Addition of AC Smart Seal

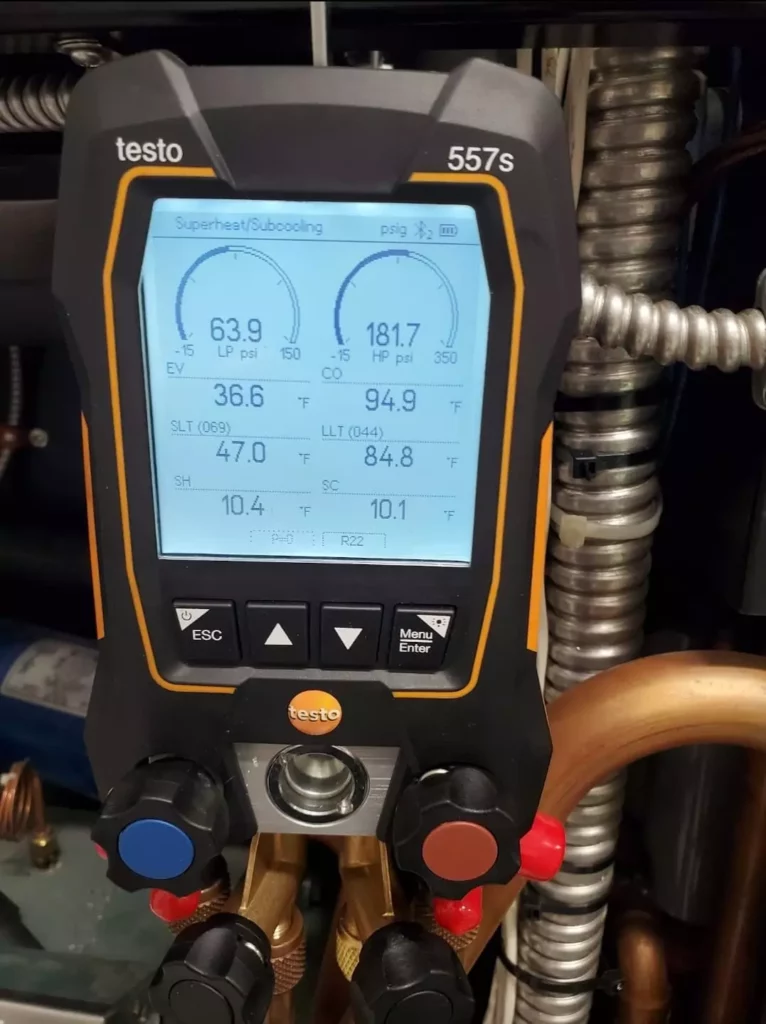

System operation after the addition of refrigerant charge and TX valve adjustment

I added the sealant and charged the system using superheat and subcooling as my guide.

I returned a few months later to check on the system, which was still functioning with a full charge.

I used my leak detector in the same area it had registered a leak on my previous visit, and it didn’t pick up anything.

I was also back there a few days before writing this article, and the charge was still good.

In Conclusion

The purists may not agree, but these tests that I have conducted over the last four years in various applications have revealed zero system failures and, in the above case, showed no detection of a refrigerant leak post-use of the sealant.

Verification of a leak and finding the leak are essential to the process, and education of and testing the product is a must.

Next, the application must fit.

In this case, a very small “unrepairable” type leak was the perfect candidate.