Indoor Air Monitoring To Increase IAQ

Preface: This article with embedded podcasts was designed to educate contractors on indoor air quality and indoor air quality monitoring.

Please use this article as a tool to educate your customers, help them stay informed and up to date.

The Three Main Factors

Shortly after the world was left in a kerfuffle by the Covid 19 pandemic, I jumped onto a podcast with Brandon Glancy from Aprilaire to discuss the three main factors of indoor air quality.

It was an eye opening conversation about things I knew about already but never had really spent the time to deep dive into.

The three main factors of IAQ include humidity, filtration and ventilation.

If we can control these factors while, of course, maintaining a comfortable indoor temperature, we can create superior quality indoor air in our customer’s homes and businesses, including our own.

It is extremely important for HVAC professionals to gain a strong understanding of these factors, how to capture the info, and how to rectify the issues presented from the data.

Let’s discuss these factors briefly.

Check out the podcast episode to learn more

Humidity

It seems logical that a building should be maintained at a comfortable humidity level.

Too much humidity can create moisture and potential mold issues, too little can make it feel dry and create static electricity when sliding on the work pants in the morning.

Too high or too low can be a determining factor in building material damage, such as flooring, reports are stating that airborne viruses travel easier in dry air.

I have also read several reports that show higher humidity levels help to contain viruses as they are contained in “heavier” water droplets that eventually fall to the ground.

The same reports state that 40% – 60% RH is the ideal set point to help with the spread of viruses.

Keep in mind that excessive humidity can create condensation on windows or areas of a building with air infiltration in colder ambient temperatures.

This happens because the building material is at or below the air’s dew point.

Keep this in mind when setting up indoor humidity; this can also be attributed to poor ventilation as well, especially while cooking.

Generally speaking, we should humidify a space in the winter and dehumidify a space in the summer.

There are many products on the market that can help with this.

An air conditioning system will remove moisture just by nature of design; when moisture embedded in the air contacts the cold evaporator coil, the water vapor will condense, flow down the coil into the drain pan, and exit out the drain line.

But what if the humidity level in the home or building is still high once the thermostat has been satisfied?

At this point, further, de-humidification is needed.

A dedicated de-humidifier can help with this task without further cooling the space.

This is where monitoring is important.

If the thermostat in the space has been satisfied as per the thermostat cooling set point, but the humidity percentage is still high, the space is at risk for moisture damage to building materials and potential mold issues.

De-humidifiers work by first cooling the air to remove moisture like a traditional air conditioning system and then re-heat the air so it doesn’t further drop the temperature in the space.

Example of an Aprilaire 1830 70-pint dehumidifier

Filtration

During my career I have changed out many MERV 8 filters (MERV stands for minimum efficiency rating value).

This has been the norm, they do fairly well to protect equipment from dirt/debris, but a good evaporator cleaning is still needed every so often.

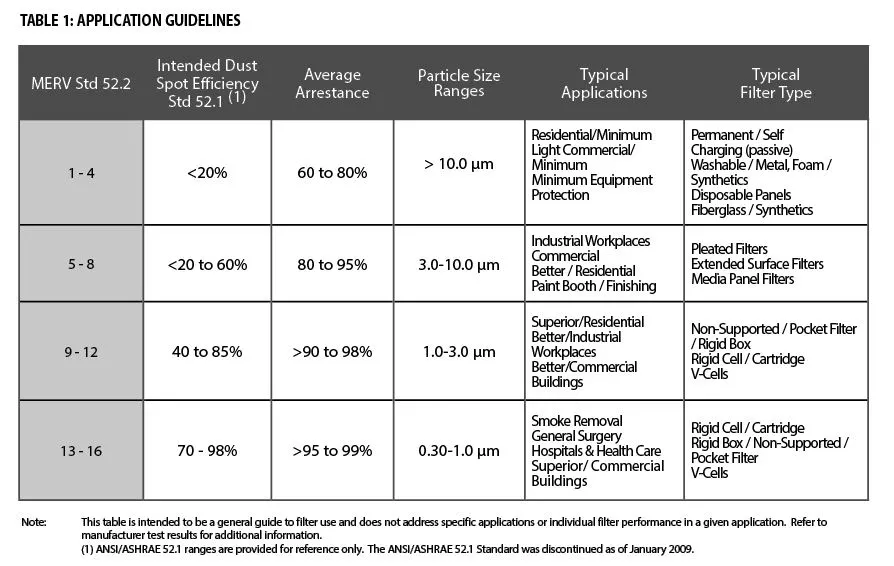

The MERV rating system was developed by ASHRAE (The American Society of Heating Refrigeration an Air Conditioning Engineers).

In general, the system was created to show the effectiveness of each filter in each MERV category.

Later in the article, I will share a chart that helps better explain.

During my podcast episode with Brandon, we discussed how MERV 13 should be the minimum requirement to protect the equipment and filter out particulate that can be harmful to humans.

Being able to measure PM2.5 in a space is extremely important, especially when planning a filtration solution for a particular space.

PM2.5, in general terms, is a measurement of particulate in the air and is an industry measurement standard, PM stands for “particulate matter,” and 2.5 is the measurement of the particle, measured at 2.5 micrometers.

Why should we be concerned with measuring PM2.5?

The particulate matter at this size and below is classified as fine and can pose greater health risks.

This is why the industry is pointing at MERV 13 as a minimum standard to protect humans.

A MERV 13 filter has the capability of capturing particulate from 0.3 to 1 micrometer, according to the chart below, which is linked to an article by the National Air Filtration Association.

The Covid 19 pandemic has had homeowners and building managers inquiring about MERV 13 filters.

I would encourage HVAC contractors to not blindly install a MERV 13 filter and consider it done.

An air flow baseline test should be performed with the existing filter and then with the MERV 13 to ensure the system can handle the added air flow resistance.

A cooling and heating check should also be performed as well to ensure there is no excessive temperature rise across the heat exchanger and cooling system is not in jeopardy of freezing due to potentially lower air flow.

It is also recommended that the filter is monitored periodically as it may load up faster depending on the environment.

Ventilation

Ventilation plays a massive role in IAQ.

There is no better way to ventilate than to rid of existing air and then to replace it with new outside air, the best way to accomplish this is with an HRV (heat recovery ventilator) or an ERV (energy recovery ventilator) depending on the needed requirements.

By not ventilating air, there can be a potential build up of VOCs (volatile organic compounds), CO2 (carbon dioxide) and moisture.

I have an HRV in my home and ran an experiment.

With the HRV off, the home accumulated approximately 1100 ppm in CO2, with the ERV on for 24 hours, the CO2 dropped off to approximately 700 ppm.

Depending on where you live, outdoor CO2 is approximately 400 ppm.

The maximum recommended CO2 ppm indoors as per ASHRAE is 1000 ppm.

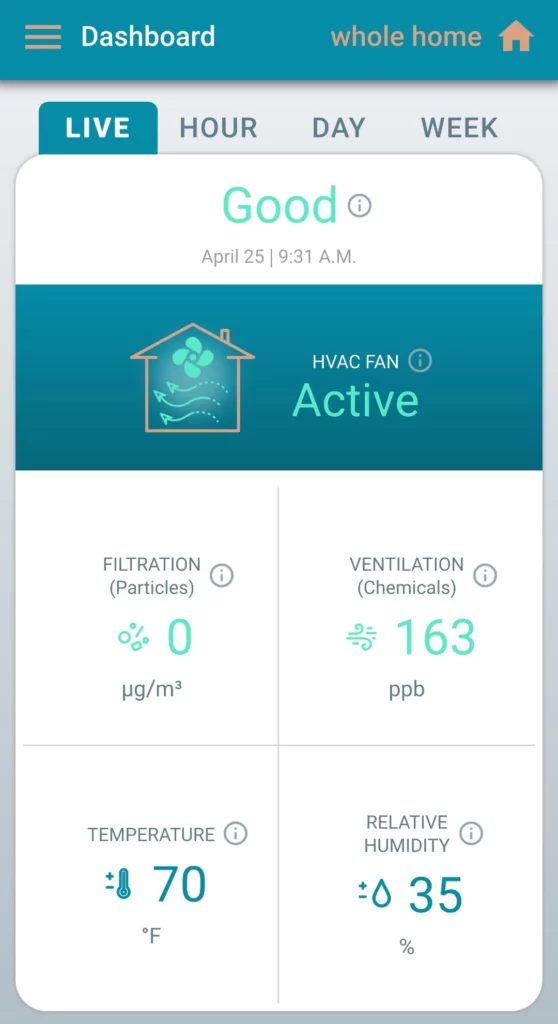

I ran an experiment with the HAVEN IAQ monitor.

I sprayed a popular glass cleaner into the return air grill and watched the VOCs rise.

The experiment was performed in two parts, and the first experiment was performed with the HRV running at minimum speed, and the second part was performed with the HRV off.

The same return air grill was used for both experiments, 5 sprays of cleaner were performed for each experiment, and there was a one-hour span after shutting down the HRV.

You’ll notice from the images below that the chemical content (VOCs) is much lower with the HRV running at minimum speed before the introduction of chemicals and relatively higher with the HRV off.

The introduction of chemicals increased the VOC content from the initial baseline test in both experiments, and anecdotally, with the HRV off, the smell of chemicals was noticed almost instantly around the home.

This is why monitoring plays a huge role in IAQ; if we don’t monitor indoor air, we can’t provide a solution to repair the issue.

In this case, the evidence shows that adding a ventilation system will help with overall VOC content within the space.

These tests were performed with the Haven IAQ Central Air Monitor, a duct-mounted, HVAC-integrated, whole-home, professionally supported IAQ strategy.

Haven IAQ app readings with HRV at minimum speed before chemical introduction

Haven IAQ app readings with HRV at minimum speed after chemical introduction

Haven IAQ app readings with HRV off before chemical introduction

Haven IAQ app readings with HRV off after chemical introduction

Here is another experiment I performed using the Haven IAQ monitor measuring PM2.5 in the return air duct before the filter

Table Top IAQ Monitors

Here is a piece written by Ben Reed on table top IAQ monitors.

Indoor air quality monitors come in different form factors – some sit on your counter or table, some have a battery and can be carried around, while others are mounted to the wall.

Most have the ability to measure the amount of particles and chemicals at varying degrees of accuracy and repeatability, though some devices are equipped with specialized sensors for certain gases or radon.

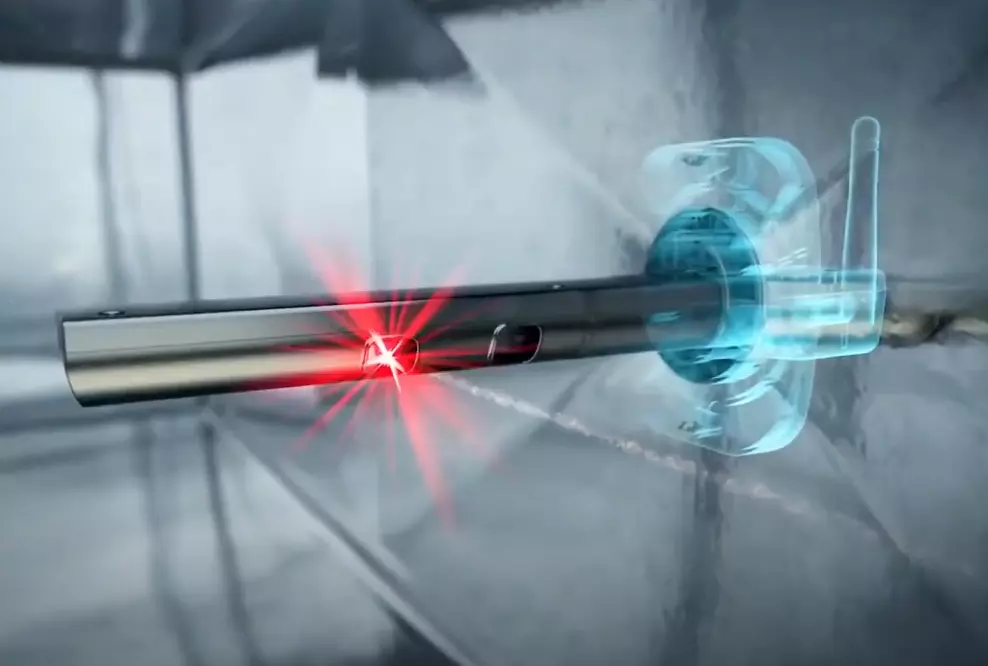

One attribute these indoor air quality monitors have in common is that they measure air only in the room where they are currently placed.

Portable monitors can be moved from room to room, but they can never measure all rooms at once.

In addition, most stationary or portable monitors measure particles using the same technique: a small fan that forces the air through a laser beam.

This technique works well, but these small fans have mechanical parts that can fail if the device is dropped, the motor or bearing fails, or too many large particles clog the tiny air channel.

To summarize, common air quality monitors only measure one room at a time and have moving parts that can fail after a few years of use.

Most modern single-family homes have central air systems that are designed to move the air throughout the whole home during heating or cooling.

Generally speaking, a home’s air is circulated by the central HVAC system first through the return ductwork, then into the filter, air handler, then back out to the home via the supply ductwork.

So why monitor the air in only one room if there is a location where all of a home’s air is being moved through?

In Duct Central IAQ Monitoring

Ben is the VP of Products at Haven IAQ by Tzoa, and their team reached out to me a few months back to perform an install and testing of their in-duct central IAQ monitor or central air monitor or CAM for short.

I am always intrigued by new technology and learning intensely about the HVAC industry, which I gladly accepted.

The installation was simplified through an instructional YouTube video and walk-through on the Haven IAQ app.

The installation simply requires a small hole in the duct, a 24v power source (from the air handler, or plug in source), and minimal setup on the app.

This work should be performed by a trained HVAC professional.

The sheer advantage of a central air monitor vs. a stationary room monitor is that the home or building’s mixed air, from each room, is captured and analyzed.

While testing the Haven IAQ monitor, I got the needed info, as far as IAQ, from the Haven IAQ app.

The Haven IAQ Pro Portal provides increased analytics with trending and reporting capabilities.

Listen to Ben, and I discuss this topic on a podcast episode

Choosing The Right Solution

What all this has taught me, is there is no real “one size” fits all solution for IAQ in a space.

I recently had a customer reach out, and they wanted us to install an air purifier for a hydronic air handler in a small office space.

I recommended we analyze the air first.

I installed a Haven IAQ CAM, and what I found was interesting.

The office space is built within a larger office tower; the building air is treated during business hours but then sets back in the evening and shuts down for the energy cost savings.

Since the smaller office within the tower is occupied 24 hours, the night shift doesn’t have the advantage of fully treated indoor air; the “cooling only” supplemental air handler is left to work alone.

It cools the space just fine, but it was noticed that the humidity in the space dropped off in the evening to below 30% RH.

The VOC content was low because the ceiling space above the office has outside air infiltration, and it seemed to work well at keeping the space ventilated with fresh air.

As a building increases in age, there is a greater chance of air leakage…But that’s for a different article.

PM2.5 was also in the low range, but there is missing occupancy due Covid 19 and people working from home.

I’m finding many unoccupied sites where filters are not nearly as loaded compared to pre-pandemic.

We will need to monitor this closely once the office staff starts to move back in.

For now, the only recommendation for this site is adding a humidifier, as we have evidence to show that humidification is needed during the evening and through the night.

We will need to do further monitoring in the summer months to ensure that humidity levels don’t rise during off-building hours.

We have the technology to monitor IAQ; let’s harness it to provide the right solutions for our homes and our customers.

Finally

Check out the link to my YouTube channel for more tips, tricks, and troubleshooting videos, and check out The HVAC Know It All podcast here or on your favorite podcast app.