Expansion valves are used to inject refrigerant into the evaporator of refrigeration and AC/HP systems at a condition that will allow the refrigerant to absorb heat.

They are sized so that the amount of refrigerant they inject will closely match the calculated load on the system evaporator at a standard set of conditions.

There are many different types ranging from simple orifices and manual hand valves to highly adaptive electronic expansion valves.

However, there are only 2 different classes of expansion valves: fixed and adaptive.

Fixed Expansion Valves

Fixed orifice expansion valves are simple devices that cannot change the amount of refrigerant injected into the evaporator to meet changes in the evaporator heat load.

This is not to say that the amount of refrigerant they inject never changes.

It is the amount injected that does not change purposefully to match a new heat load.

The most common type of fixed orifice devices are piston and capillary tubes.

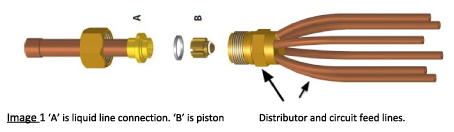

Pistons are essentially a hole in a piece of metal held in a distributor that is attached to the inlet of an evaporator.

Image 1 shows a piston (B) and the distributor to the right of it.

The size of the hole and the pressure difference across it determines the amount of flow through it.

You will notice that I added the qualifier “at a standard set of conditions” in the first paragraph when describing how metering devices are sized.

This is especially true for piston-type devices as the flow through one is determined by the pressure difference across it, which is the difference between the evaporator and condensing pressures.

If you are going to size/select one for a system, you need to use a set of conditions that the system will operate in, and it should be a set of values that everyone agrees upon and therefore is standardized across that application.

These values are the evaporator and condensing pressure and include values for superheat and subcooling.

An example of a standardized air conditioning set of values would be ARI A/C CT 130F which specifies a 45F evaporator temperature, 130F condensing temperature, 20F useful superheat, and 15F subcooling.

Using standardized conditions allows the industry to match up components based on capacity so that they will work with each other in the system.

If the difference between the condensing and evaporator pressures determines the flow through a piston orifice, then when these values change, so will the flow.

Therefore, you will see lower values of evaporator superheat (And subcooling, for that matter.) when the outside temperature is high.

If you look at a charging chart for a piston-equipped air conditioning system, you will notice that for a given value of indoor Wb temperature, the superheat target value will increase when the outdoor temperature decreases and vice versa.

On a hot day with low humidity, the evaporator superheat can be in the single digits.

A dirty condenser or poor airflow on the same day can result in a flooded compressor.

Conversely, on a cooler day with rain falling, superheat is high enough to result in poor dehumidification.

Capillary tubes are long, narrow, diameter tubing and have some capacity for adapting to changes in condenser pressure.

This is due to the amount of subcooling decreasing as condensing pressure increases in systems that have a critical charge.

When subcooling is reduced, the pressure drop that occurs in the cap tube will result in the liquid flashing to a vapor sooner, and since vapor takes up more volume than liquid, this reduces the amount of refrigerant that can flow through the cap tube.

However, cap tubes still work best when high and low side pressures are steady.

Cap tubes are sized by determining the load at the desired conditions and then picking a cap tube of the recommended diameter and cutting it to the recommended length.

If you mess this up, expect either too much or too little flow into the evaporator and an unhappy system.

🔊 Listen to Jamie Kitchen and Gary McCreadie discuss superheat as it pertains to adaptive vs. fixed metering devices and subscribe to the HVAC Know It All Podcast.

Adaptive Expansion Valves

The other main class of expansion valves is the adaptive type.

Adaptive means that the expansion valve will respond to a change in load by changing how much refrigerant is injected into the evaporator.

The most popular of these is the thermal expansion valve or TXV.

A TXV uses pressure developed in a sensing bulb mounted on the evaporator outlet tube as well as the pressure in the evaporator to act as signals.

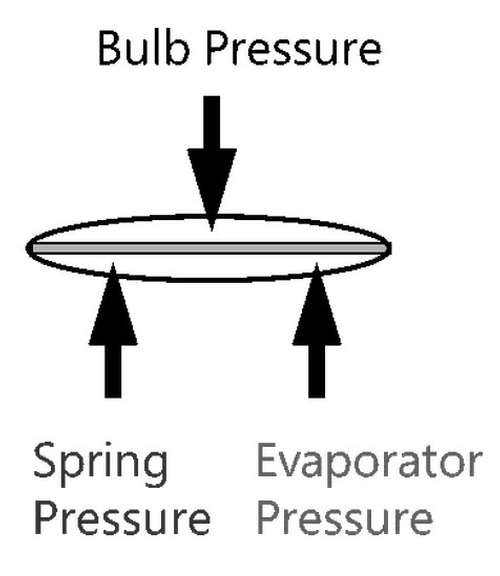

If you look at Image 2, you will see how these signals are applied across a diaphragm located in the power element of the TXV.

In this case, the pressures act as a force trying to open and close the valve and oppose each other.

On the bottom of the diaphragm, the evaporator pressure is applied along with a second force supplied by a spring.

This spring is the superheat spring.

On top of the diaphragm, the pressure from the sensing bulb is applied.

The sensing bulb is the opening force, while the evaporator pressure and superheat spring are the closing forces.

Evaporator Load

If the load on the evaporator increases, initially, there will not be enough refrigerant in the evaporator to match the higher load.

The increased heat being absorbed by the refrigerant will result in the liquid boiling off sooner and only vapor left farther up the evaporator circuit.

This vapor still absorbs heat and will result in excessive superheat at the evaporator outlet. This will increase the sensing bulb temperature and pressure.

This bulb pressure is transmitted through the cap tube connecting the bulb to the TXV power head and onto the top of the diaphragm.

Since this is an opening force, it will overcome the evaporator and spring force and drive the valve open. The increased refrigerant in the evaporator will reduce the superheat of the leaving refrigerant.

When you adjust the superheat setting on a TXV, you change the force applied by the superheat spring.

This force ensures there is always a minimum amount of superheat present in the evaporator to protect the compressor against flood back.

It is recommended not to adjust the superheat setting until you have eliminated all other potential causes of incorrect superheat or it has been advised by the manufacturer to do so.

Adjusting superheat on a TXV when another issue is the problem can turn something that would have been a straightforward repair into something more involved and expensive.

For evaporators that have multiple circuits, a distributor is used to feed the different circuits.

The distributor (See image 1) introduces a large pressure drop between the TXV outlet and the outlet of the evaporator.

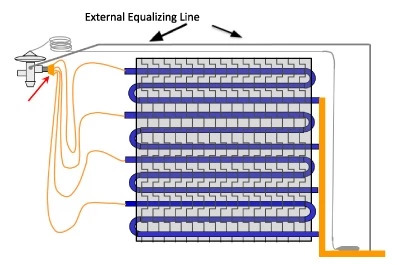

This pressure drop must be accounted for, so in these types of applications, an external equalized TXV is used.

These take the pressure from the evaporator outlet after all the pressure drops have occurred and apply it to the underside of the TXV diaphragm through a tube connected from the side of the TXV to the outlet of the evaporator (See Image 3).

If this was not done, the temperature equivalent of the pressure drop would be added to the superheat required to open the TXV, and it would underfeed the evaporator.

For simpler evaporators with single circuits and little pressure drop, an internal equalized TXV can be used.

These apply the pressure directly from the evaporator inlet/TXV outlet under the diaphragm.

While you can use an external equalized TXV when it is not necessary, you must never use an internal equalized TXV when an external one is required.

Electronic Expansion Valve

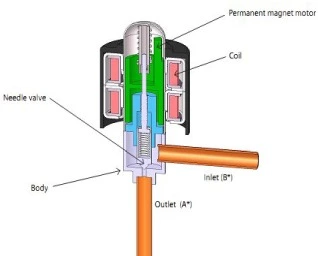

The other major type of adaptive expansion valve is the electronic expansion valve or EEV.

They consist of a valve body and motor or solenoid to drive it open and closed.

A controller is used that can be programmed for different refrigerants and superheat values to control to.

This uses a pressure and temperature signal to determine the evaporator saturation temperature and the amount of superheat present and adjusts the opening and closing of the valve according to the values set in the programming.

There is a lot of flexibility in how the valve can control, and they can be used across a wide range of applications, from very low-temperature freezers up to comfort cooling.

Often, they are set to maintain a fixed superheat value that is close to optimal at the conditions that the systems will operate under.

Other designs will always be trying to reduce the superheat as low as possible while still being stable and offer even more energy-saving possibilities (See Image 4)

EEVs come in 2 main types, stepper motor valves and pulse width modulated.

The stepper motor valve will drive the valve open or closed in small incremental steps using a stepper motor that turns in one direction when a positive signal is sent to it and in the opposite direction when a negative signal is applied. (Image 5)

How fast the valve opens or closed can be set, as well as minimum and maximum opening ranges.

Pulse width modulated valves are essentially robust solenoid valves that will either be 100% open or 100% closed.

How long the valve remains open over a given amount of time vs. closed determines how much refrigerant is injected into the evaporator.

These valves have the advantage of good oil return but must be installed away from other line components to avoid liquid hammer issues.

Conclusion

To summarize, fixed metering devices work well when conditions are constant, and evaporator loads do not change much.

When conditions can vary, such as condensing pressure or evaporator heat loads, care must be taken to ensure that the valve will meet the requirements but will not overfeed the evaporator and slug the compressor.

Adaptive metering devices allow for greater flexibility as they will open or close to meet demand regardless of changing conditions if the conditions fall within a specific range.

TXV can throttle to half of its rated capacity and then open to provide as much as 30% above its rated capacity when the situation calls for it.

EEVs have an even greater throttling range on the low end and can control loads down to 20% of their rated capacity or even less.

Learn More with HVAC Knowitall

Elevate your HVAC expertise and outshine your peers by delving into our informative blog articles, listening to our industry-specific podcast, and subscribe to our YouTube channel, where we share valuable insights tailored specifically for HVAC technicians seeking to enhance their business and provide exceptional service.